Hawk Performance HB701P.723 SD MERCEDES-BENZ Front Brake Pads GLE Class C292 M Class W166

224.99€

GET IN TOUCH

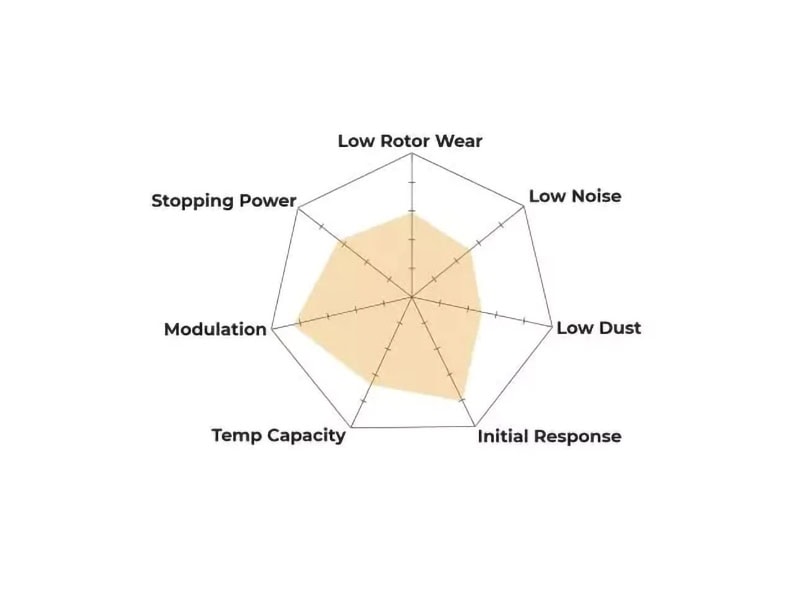

The Hawk Performance SuperDuty Brake Pads are engineered for Mercedes SUV owners who demand extreme braking performance in high-load, high-stress conditions. Purpose-built for utility-focused applications, these pads are ideal for Mercedes GLE and M-Class models used for towing, hauling, or operating in rugged environments. Whether you’re descending a mountain pass with a trailer or relying on your SUV for commercial work, the SuperDuty compound is designed to deliver maximum stopping power and long-term reliability.

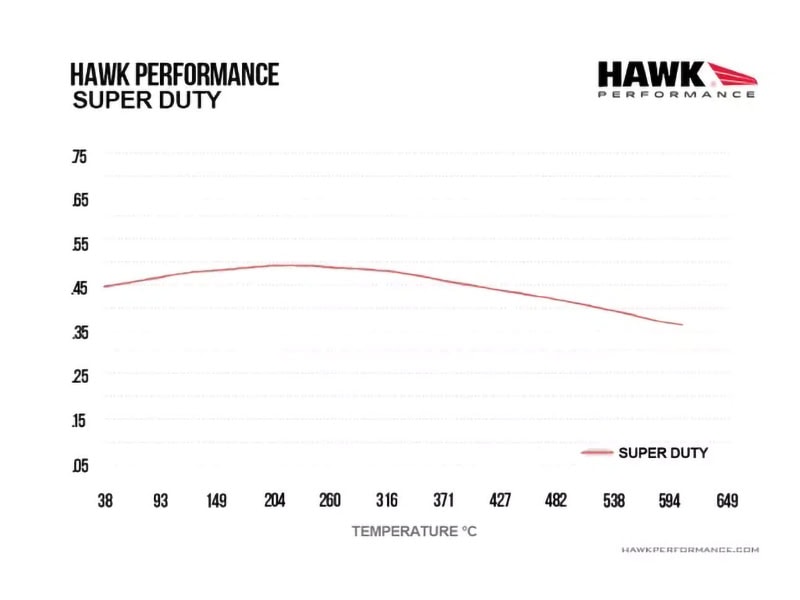

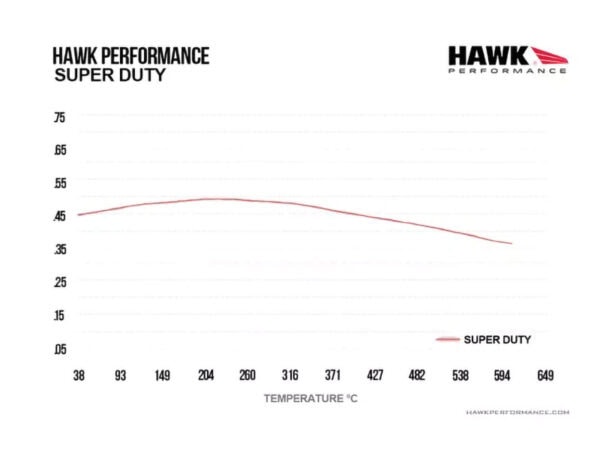

At the heart of the SuperDuty pad is Hawk’s advanced Ferro-Carbon high-performance friction material, developed from aerospace and motorsport technology. This compound offers a substantial increase in brake torque and fade resistance over OEM pads, providing confident, consistent performance even during repeated hard stops. With an effective temperature range from 38°C to 399°C, and an optimal operating zone between 38°C and 260°C, these pads are built to handle the demands of fully loaded, high-output Mercedes SUVs.

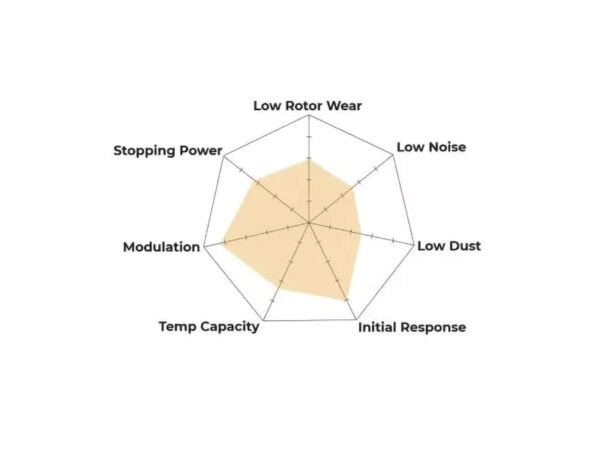

Compared to standard factory pads, Hawk SuperDuty Brake Pads reduce stopping distances, improve brake pedal feel, and resist fade under load—all while offering longer pad life and reduced rotor wear. Their rugged construction makes them the ideal solution for Mercedes-Benz SUV drivers who frequently tow, carry heavy cargo, or demand elevated performance in challenging driving conditions.

While not intended for casual or personal-use driving, the Hawk Performance SuperDuty Brake Pads are the perfect upgrade for Mercedes GLE and M-Class owners who expect their vehicle to perform under pressure. When safety, control, and endurance matter most, SuperDuty pads deliver commercial-grade stopping power with the precision expected of the Mercedes name.

FEATURES

- Strong & balanced initial bite, hot or cold

- Greater fade resistance

- Ferro-Carbon friction

- Low dust output

- Excellent pad & rotor life

- Low torque

- 38-260 °C optimal operating temperatures

APPLICATIONS

- Dodge / Durango (3rd Gen) 2010-Present / SUV (WD) 2011-Present / Durango 3.6 2011-Present

- Dodge / Durango (3rd Gen) 2010-Present / SUV (WD) 2011-Present / Durango R/T 5.7 2011-Present

- Jeep / Grand Cherokee (4th Gen) 2010-2021 / SUV (WK2) 2010-2021 / Grand Cherokee 3.0 TD 2010-2021

- Jeep / Grand Cherokee (4th Gen) 2010-2021 / SUV (WK2) 2010-2021 / Grand Cherokee 3.6 2010-2018

- Jeep / Grand Cherokee (4th Gen) 2010-2021 / SUV (WK2) 2010-2021 / Grand Cherokee 5.7 2010-2018

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / Coupe (C292) 2015-Present / GLE350D Coupe 3.0 TD 2015-Present

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / Coupe (C292) 2015-Present / GLE400 Coupe 3.0 Twin Turbo 2015-2018

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / SUV (W166) 2015-2018 / GLE250D 2.1 Twin TD 2015-2018

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / SUV (W166) 2015-2018 / GLE250D 4-Matic 2.1 Twin TD 2015-2018

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / SUV (W166) 2015-2018 / GLE350D 3.0 TD 2015-2018

- Mercedes-Benz / GLE-Class (1st Gen) 2015-2018 / SUV (W166) 2015-2018 / GLE400 3.0 Twin Turbo 2015-2018

- Mercedes-Benz / M-Class (3rd Gen) 2011-2015 / SUV (W166) 2011-2015 / ML250D 2.1 Twin TD 2011-2015

- Mercedes-Benz / M-Class (3rd Gen) 2011-2015 / SUV (W166) 2011-2015 / ML350 3.5 2011-2015

- Mercedes-Benz / M-Class (3rd Gen) 2011-2015 / SUV (W166) 2011-2015 / ML350D 3.0 TD 2011-2015

- Mercedes-Benz / M-Class (3rd Gen) 2011-2015 / SUV (W166) 2011-2015 / ML400 3.0 Twin Turbo 2012-2015

Images are for illustration purposes only

All Hawk Performance compounds are not compatible with carbon ceramic brake discs. Hawk pads are designed to work with traditional Iron/Metal brake discs.

ADDITIONAL INFORMATION:

| Manufacturer | Hawk |

|---|---|

| Package Contents | 1 set of pads for two calipers |

| Brake Pads Compound | Semi-Metallic |

| Brake Pads Type | Street |

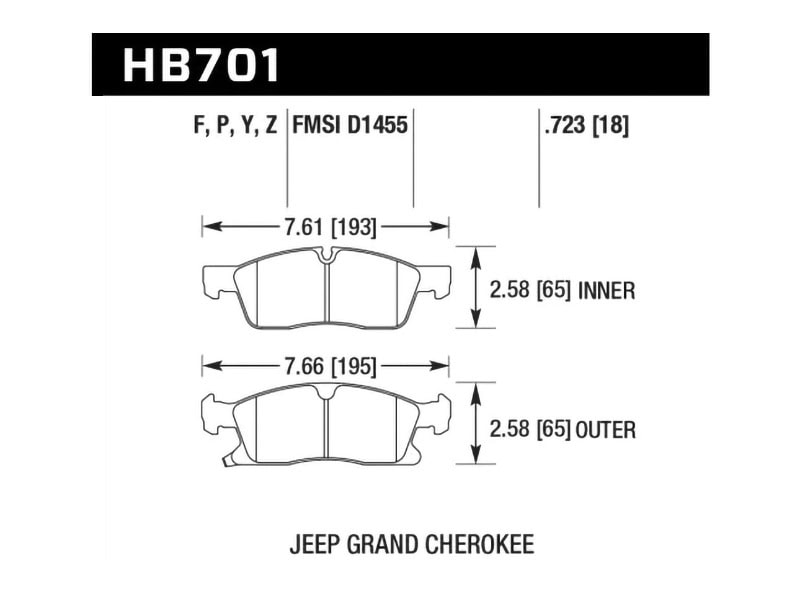

| Inner Pad Thickness (mm) | 18,36 |

| Inner Pad Height (mm) | 65 |

| Inner Pad Width (mm) | 193 |

| Pad Label | SD |

| FMSI Number | D1455-8655 |

| UPC EAN Code | 840653083377 |

PREPREG is a common term for a reinforcing fabric such carbon which has been pre-impregnated with a resin system. This resin system (typically epoxy) already includes the proper curing agent. As a result, the prepreg is ready to be laid into the mold without the addition of any more resin. In order for the laminate to cure, an autoclave production process is used, a combination of high pressure and heat.

- Maximum strength and performance characterictics. In a hand layup production process, it is difficult to achieve 50% fabric and 50% resin content. Typical hand laminates, even when vacuum bagged, end up with a significant amount of excess resin. Excess resin increases brittleness and reduces overall strength properties. On the other hand, most prepregs contain around 35% resin. This is ideal for maximum cured properties and generally impossible to achieve in normal hand lamination.

- Uniformity and repeatability. The prepreg is of uniform thickness and each part coming out of the mold may theoretically be the same. Vacuum bagging technology may have some errors in processing, but prepreg ensures production consistency.

- Reduce curing time. After the thermal curing cycle, no need to wait for the standard 48 hours can be fully cured.

- Aesthetics. Although prepreg processing still requires mold preparation and demoulding, prepreg processing eliminates air bubbles, makes it easier to obtain a smooth, glossy surface as well as eliminates any seaming lines.

We offer free tracked shipping on all orders within mainland EU. Orders to remote areas such as Malta, Cyprus, and Iceland may incur a surcharge. Worldwide shipping is also available—please contact us for a quote.

Most orders dispatch within one business day (Monday to Friday). EU delivery takes 3–5 working days from dispatch, and tracking details will be provided via email once your order has shipped.

Please note that import taxes may apply outside the EU, and these are the responsibility of the buyer. Some items may ship directly from our suppliers and may have varying delivery times. If an item is out of stock, we will contact you to discuss the available options.

RETURNS

Changed your mind? You can return unused, uninstalled items in original packaging within 30 days of delivery. Return shipping is the customer’s responsibility unless the item is faulty.

Custom, used, or built-to-order items are non-returnable.

Once we receive and inspect your return, refunds are typically processed within 10 business days.

If your item is damaged or incorrect, contact us within 48 hours with photos and order details.

WARRANTY

All VA and VA Motorsports products come with a 1-year limited warranty covering manufacturing defects and fitment issues. For third-party items, warranty terms vary by brand—please check the product listing or contact us for details.

This warranty does not cover wear and tear, incorrect installation, cosmetic damage, labor, or third-party costs.

To start a claim, email us with your order number, issue description, and photos. If the claim is approved, we’ll offer a replacement, store credit, or a refund.

Leave a Reply

You must be logged in to post a comment.