ACL Race Series Connecting Rod Bearing Set BMW S50B32

329.99€

GET IN TOUCH

The ACL Race Series Connecting Rod Bearing Set for BMW’s S50B32 engine is made for those who drive their E36 M3 the way it was meant to be driven. The 3.2-liter straight-six thrives on revs and precision, but once you increase compression, chase more power, or keep it pinned on track days, the limits of factory bearings start to show. ACL’s Race Series bearings step in where OEM parts can’t—handling heat, load, and high RPMs with strength and consistency.

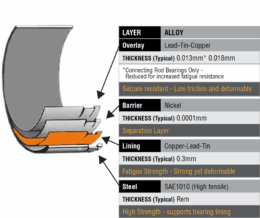

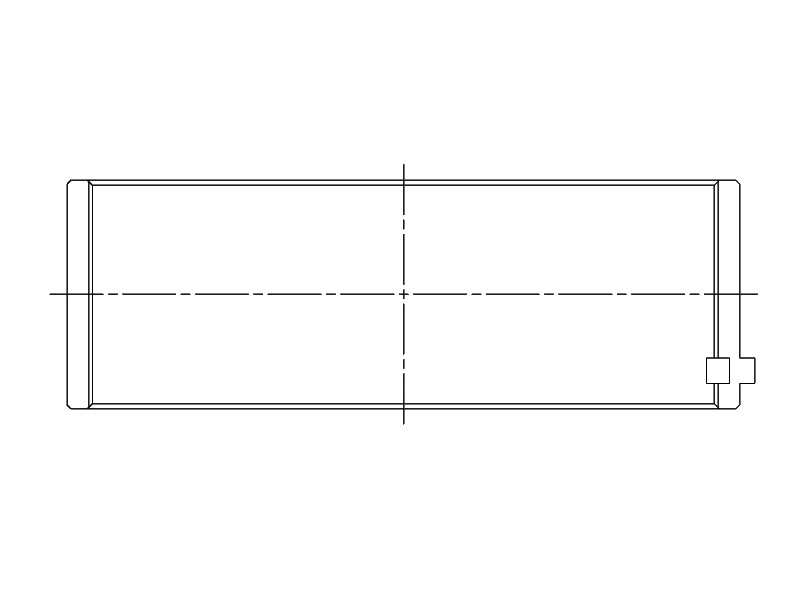

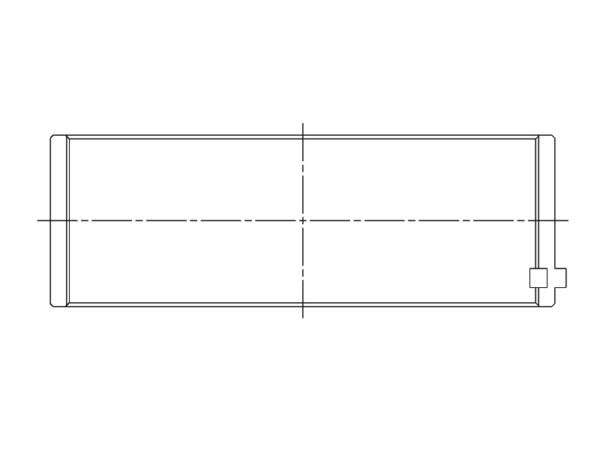

Each bearing features ACL’s proven tri-metal construction: a hardened steel backing for rigidity, a copper-lead layer for strength under load, and a precision overlay that maintains a consistent oil film under intense pressure. This design keeps friction in check, oil pressure stable, and crankshaft journals protected—even when the S50B32 is running at its sharpest edge.

The Race Series material is the same trusted in motorsport engines around the world. It delivers exceptional fatigue resistance, dependable clearances, and smooth oil control under stress. Built for sustained performance, these bearings endure the punishment of repeated high-RPM runs, quick throttle transitions, and the thermal strain that comes with serious track use.

Installation is simple and precise. ACL engineered these bearings as a direct-fit replacement for the BMW S50B32 engine found in the European-spec E36 M3. No machining, no adjustments—just perfect OEM geometry backed by race-grade strength.

For E36 M3 owners pushing their cars beyond factory limits, ACL Race Series bearings are the upgrade that keeps the legendary S50B32 spinning smooth and strong. They bring peace of mind when every rev counts, ensuring the heart of your engine stays cool, balanced, and ready for the next lap.

FEATURES

- High-performance upgrade: ACL Race Series bearings provide a stronger, more reliable replacement for BMW’s factory components—designed to handle the heat, load, and high RPM of the S50B32 engine found in the European E36 M3.

- Precision-engineered for BMW performance: Developed to eliminate rod bearing wear and oil pressure inconsistencies often seen in high-output BMW engines, ensuring consistent lubrication and smooth operation across the entire rev range.

- Factory-grade accuracy: Manufactured to exact BMW tolerances for precise clearances, stable oil pressure, and dependable performance under demanding driving conditions.

- Race-proven tri-metal construction: Features a hardened steel backing, copper-lead intermediate layer, and precision overlay that deliver outstanding strength, fatigue resistance, and stable oil film retention even under track stress.

- Improved bearing contact: The non-tin flash surface enhances fitment stability, reducing distortion and maintaining perfect alignment through prolonged high-load and high-temperature use.

- Built for endurance and confidence: Tested in professional motorsport and high-performance builds, these bearings give the S50B32 the durability and peace of mind needed for hard driving—on road, track, or during extended high-RPM sessions.

APPLICATIONS

- 1995–1998 BMW S50B32 E30 M3 3.2L

NOTES

Specifications for STD size only.

Includes upper and lower bearing shells for a complete rod bearing replacement.

ADDITIONAL INFORMATION:

| Brand | |

|---|---|

| Half Type | Identical halves |

| Material | F781 |

| Min. Std Shaft Size | 48,975 mm / 1.9281 in |

| Max. Std Shaft Size | 48,991 mm / 1.9288 in |

| Min. Std Tunnel Size | 53 mm / 2.0866 in |

| Max. Std Tunnel Size | 53,015 mm / 2.0872 in |

| Max Wall at Crown | 1,993 mm / 0.0785 in |

| Max Overall Length | 18 mm / 0.7087 in |

PREPREG is a common term for a reinforcing fabric such carbon which has been pre-impregnated with a resin system. This resin system (typically epoxy) already includes the proper curing agent. As a result, the prepreg is ready to be laid into the mold without the addition of any more resin. In order for the laminate to cure, an autoclave production process is used, a combination of high pressure and heat.

- Maximum strength and performance characterictics. In a hand layup production process, it is difficult to achieve 50% fabric and 50% resin content. Typical hand laminates, even when vacuum bagged, end up with a significant amount of excess resin. Excess resin increases brittleness and reduces overall strength properties. On the other hand, most prepregs contain around 35% resin. This is ideal for maximum cured properties and generally impossible to achieve in normal hand lamination.

- Uniformity and repeatability. The prepreg is of uniform thickness and each part coming out of the mold may theoretically be the same. Vacuum bagging technology may have some errors in processing, but prepreg ensures production consistency.

- Reduce curing time. After the thermal curing cycle, no need to wait for the standard 48 hours can be fully cured.

- Aesthetics. Although prepreg processing still requires mold preparation and demoulding, prepreg processing eliminates air bubbles, makes it easier to obtain a smooth, glossy surface as well as eliminates any seaming lines.

We offer free tracked shipping on all orders within mainland EU. Orders to remote areas such as Malta, Cyprus, and Iceland may incur a surcharge. Worldwide shipping is also available—please contact us for a quote.

Most orders dispatch within one business day (Monday to Friday). EU delivery takes 3–5 working days from dispatch, and tracking details will be provided via email once your order has shipped.

Please note that import taxes may apply outside the EU, and these are the responsibility of the buyer. Some items may ship directly from our suppliers and may have varying delivery times. If an item is out of stock, we will contact you to discuss the available options.

RETURNS

Changed your mind? You can return unused, uninstalled items in original packaging within 30 days of delivery. Return shipping is the customer’s responsibility unless the item is faulty.

Custom, used, or built-to-order items are non-returnable.

Once we receive and inspect your return, refunds are typically processed within 10 business days.

If your item is damaged or incorrect, contact us within 48 hours with photos and order details.

WARRANTY

All VA and VA Motorsports products come with a 1-year limited warranty covering manufacturing defects and fitment issues. For third-party items, warranty terms vary by brand—please check the product listing or contact us for details.

This warranty does not cover wear and tear, incorrect installation, cosmetic damage, labor, or third-party costs.

To start a claim, email us with your order number, issue description, and photos. If the claim is approved, we’ll offer a replacement, store credit, or a refund.

Leave a Reply

You must be logged in to post a comment.