Hawk Performance HB108V.560 DTC-50 Porsche Rear Brake Pads 911 991.2 Turbo GT2 RS

274.99€

GET IN TOUCH

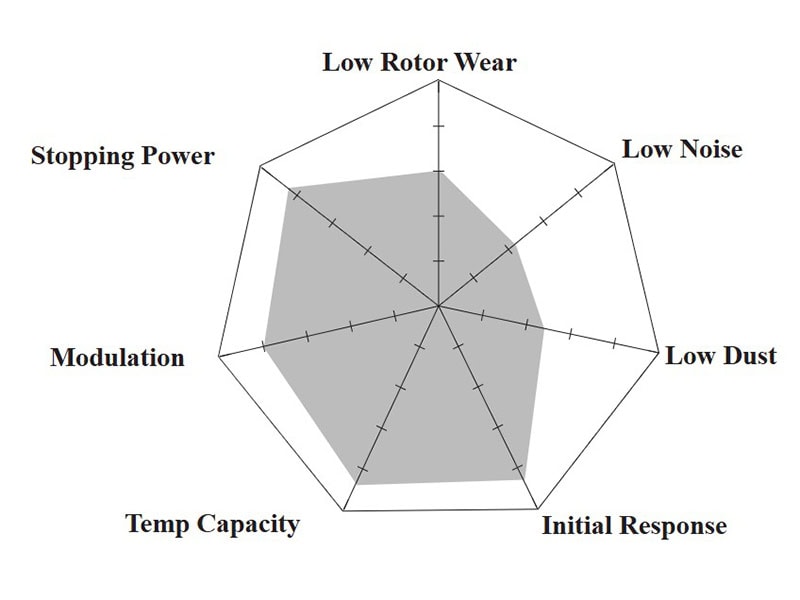

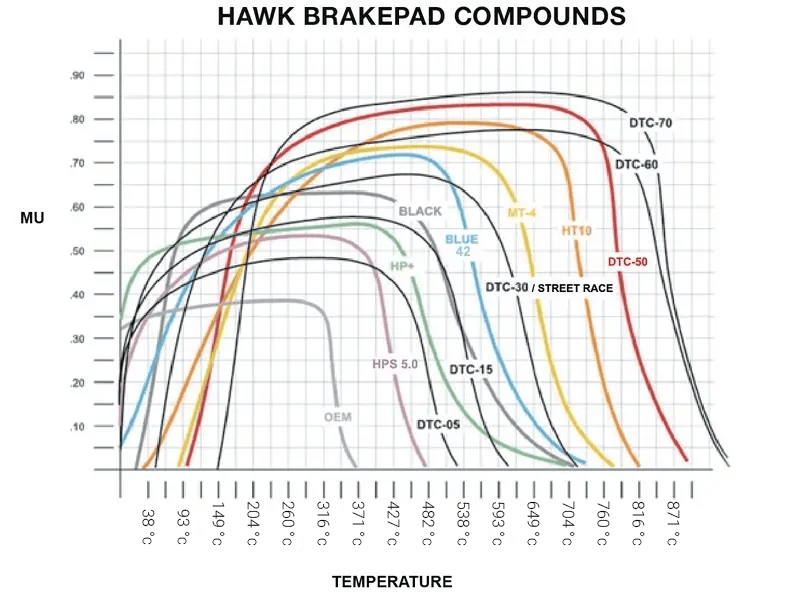

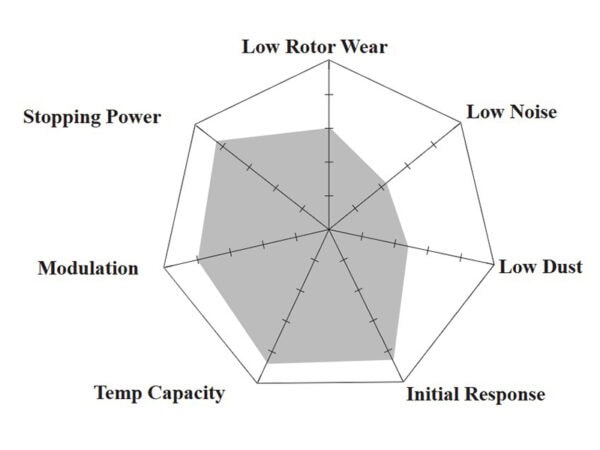

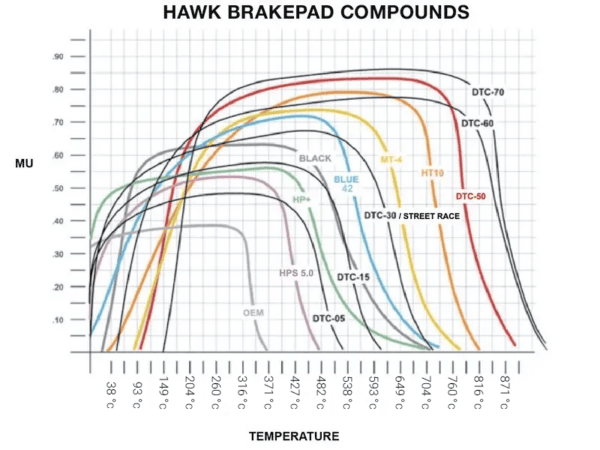

The Hawk Performance DTC-50 Racing Brake Pads are engineered for elite drivers and professional-level racing applications where high-speed braking precision, thermal stability, and maximum frictional control are essential. Positioned between the DTC-30 and the more aggressive DTC-60/70 compounds, the DTC-50 offers a unique balance of moderate initial bite, linear torque response, and smooth pedal feel—making it exceptionally well-suited for vehicles that demand precise brake modulation and repeatable performance in high-temperature environments.

With an optimal operating temperature range from approximately 300°C to 900°C, the DTC-50 compound maintains consistent friction even under extended heat cycles and heavy braking loads. This makes it a top choice for sprint racing, touring car events, time attack, and lightweight GT cars, where brake control and consistency often determine lap times and driver confidence. Unlike more aggressive compounds that can sometimes compromise feel for torque, the DTC-50 delivers smooth release characteristics, making it easier to trail brake effectively and manage rotation through corners.

Its medium-high torque level allows it to perform well in both front and rear axle applications, and it integrates seamlessly into split-friction setups when paired with other Hawk DTC compounds. The DTC-50 is particularly advantageous for race platforms that generate high levels of grip, but still require fine control over brake bias and pedal input.

Please note, like all Hawk DTC compounds, the DTC-50 is designed exclusively for track use. It is not intended for street driving due to its high-temperature requirements, potential for increased noise and dust, and lack of low-temperature friction performance.

If you’re looking for a racing brake pad that delivers confidence-inspiring pedal feel, consistent performance under extreme heat, and exceptional control in competitive conditions, the Hawk Performance DTC-50 Racing Brake Pads are built to meet the challenge.

FEATURES

- High torque

- Wide range of operating temperature: 300-900 °C

- Slightly aggressive initial bite with superior modulation and feel

- Ideal for high deceleration rates

APPLICATIONS

- Porsche / 911 (7th Gen) 2011-2019 / 911 Turbo (991.2) 2015-2019 / 911 GT2 RS Clubsport 3.8 Twin Turbo 2018-2019

NOTES

Images are for illustration purposes only

All Hawk Performance compounds are not compatible with carbon ceramic brake discs. Hawk pads are designed to work with traditional Iron/Metal brake discs.

ADDITIONAL INFORMATION:

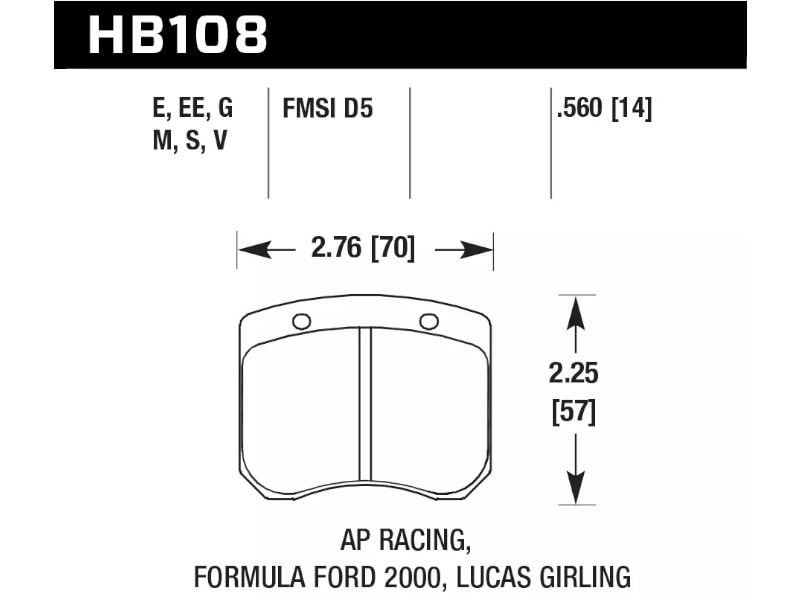

| Manufacturer | Hawk |

|---|---|

| Package Contents | 1 set of pads for two calipers |

| Brake Pads Compound | Semi-Metallic |

| Brake Pads Type | Race |

| Inner Pad Thickness (mm) | 14,22 |

| Inner Pad Height (mm) | 57 |

| Inner Pad Width (mm) | 70 |

| Pad Label | DTC-50 |

| UPC EAN Code | 840653070575 |

PREPREG is a common term for a reinforcing fabric such carbon which has been pre-impregnated with a resin system. This resin system (typically epoxy) already includes the proper curing agent. As a result, the prepreg is ready to be laid into the mold without the addition of any more resin. In order for the laminate to cure, an autoclave production process is used, a combination of high pressure and heat.

- Maximum strength and performance characterictics. In a hand layup production process, it is difficult to achieve 50% fabric and 50% resin content. Typical hand laminates, even when vacuum bagged, end up with a significant amount of excess resin. Excess resin increases brittleness and reduces overall strength properties. On the other hand, most prepregs contain around 35% resin. This is ideal for maximum cured properties and generally impossible to achieve in normal hand lamination.

- Uniformity and repeatability. The prepreg is of uniform thickness and each part coming out of the mold may theoretically be the same. Vacuum bagging technology may have some errors in processing, but prepreg ensures production consistency.

- Reduce curing time. After the thermal curing cycle, no need to wait for the standard 48 hours can be fully cured.

- Aesthetics. Although prepreg processing still requires mold preparation and demoulding, prepreg processing eliminates air bubbles, makes it easier to obtain a smooth, glossy surface as well as eliminates any seaming lines.

We offer free tracked shipping on all orders within mainland EU. Orders to remote areas such as Malta, Cyprus, and Iceland may incur a surcharge. Worldwide shipping is also available—please contact us for a quote.

Most orders dispatch within one business day (Monday to Friday). EU delivery takes 3–5 working days from dispatch, and tracking details will be provided via email once your order has shipped.

Please note that import taxes may apply outside the EU, and these are the responsibility of the buyer. Some items may ship directly from our suppliers and may have varying delivery times. If an item is out of stock, we will contact you to discuss the available options.

RETURNS

Changed your mind? You can return unused, uninstalled items in original packaging within 30 days of delivery. Return shipping is the customer’s responsibility unless the item is faulty.

Custom, used, or built-to-order items are non-returnable.

Once we receive and inspect your return, refunds are typically processed within 10 business days.

If your item is damaged or incorrect, contact us within 48 hours with photos and order details.

WARRANTY

All VA and VA Motorsports products come with a 1-year limited warranty covering manufacturing defects and fitment issues. For third-party items, warranty terms vary by brand—please check the product listing or contact us for details.

This warranty does not cover wear and tear, incorrect installation, cosmetic damage, labor, or third-party costs.

To start a claim, email us with your order number, issue description, and photos. If the claim is approved, we’ll offer a replacement, store credit, or a refund.

Leave a Reply

You must be logged in to post a comment.